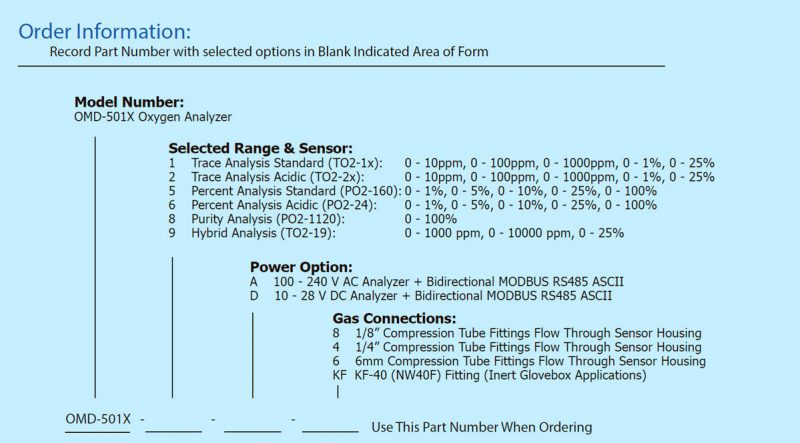

Panel mount oxygen analyzer OMD-501X

Price 2062€

Oxygen Analyzer:

The model OMD-501X oxygen analyzer combines a rugged in-line design with SSO2’s precision oxygen sensors. The result is a highly reliable and cost effective compact design with easy-to-use user interface.

Trace ranges include 0 – 10 ppm, 0 – 100 ppm, 0 – 1000ppm, 0-10000ppm and 0-25%. Percent ranges include 0 – 1%, 0 – 5%, 0 – 10%, 0 – 25%, and 0 – 100%. The analyzer can be configured for trace (parts-per-million), percent, and purity applications by the user by selecting which sensor is in use in the built-in menu.

The analog output can be manual range selected through the on board menu or the user can take ad- vantage of the auto-range feature using the RANGE ID output allowing easy interface with a PLC, DCS or other control system.

Gas connections are made with compression tube fittings or a direct fit KF-40 Housing.

Oxygen Sensor Technology:

The oxygen sensors used in the OMD-501X are based on the galvanic electrochemical fuel cell principal. All oxygen sensors are manufactured in house by Southland Sensing Ltd. under a strict quality program.

The standard cells are unaffected by other background gases such as H2, He or Hydrocarbons. The acidic cells work well when acid gases such as CO2 or Natural Gas are present.

The sensors are self-contained and minimal maintenance is required – no need to clean electrodes or add electrolyte.

The SSO2 precision oxygen sensors offer excellent performance, accuracy and stability while maximizing the expected life.

|

|

|

| H6 KF-40 Sensor Housing | H3 Flow Through Sensor Housing | Oxygen Sensor |

- Precision Electrochemical Sensor Technology Intuitive User-Friendly Interface

- Trace, Percent, or Purity Analysis Ranges Auto-Ranging or Manual Range Mode

- Two Adjustable Alarm Contacts w/ delay mode 1/4 DIN

- Panel Mount

- Compact Design

- Measure Oxygen from 0.01ppm to 100%

Applications:

- Inert Glove Box Systems

- Nitrogen and O2 PSA Generators

- Laboratories & Universities

- Medical Grade Oxygen Concentrators

- Air Separation Plants

- & Many Others

Power Requirements:

| Input Power | 10 – 28 V DC |

| Input Power | 100 – 240 V AC |

| Current Draw | 50 mA |

Oxygen Sensors:

TO2-1x PPM Oxygen Sensor: Trace Analysis, Standard

TO2-2x PPM Oxygen Sensor: Trace Analysis, Acidic

PO2-160 Percent Oxygen Sensor: Percent Analysis, Standard

PO2-24 Percent Oxygen Sensor: Percent Analysis, Acidic

PO2-1120 Purity Oxygen Sensor: Purity Analysis

TO2-19 Hybrid Oxygen Sensor: Percent or Trace Analysis

Oxygen sensors should be periodically calibrated. Factory recommendation is every 2 – 3 months or as the application dictates. Sensors offer excellent linearity with an air calibration, or calibrate to a certified span gas to maximize accuracy.

Specifications:

| Accuracy | +/- 1% Full Scale Range* |

| Display | LCD with Backlight |

| Dimensions | 1/4 DIN (96 x 96 x 65mm) |

| Enclosure | Anodized Aluminum |

| Classification | General Purpose |

| Temperature Rating | 0 – 50 deg C |

| Temperature Compensation | Integral |

| Alarms | 2 Adjustable w/ delay mode |

| Power | 10 – 28 VDC or 100 – 240 VAC |

| Output (Analog) | 4 – 20mA |

| Communication | Bi-Directional MODBUS RS485 ASCII |

| Range ID | 1 – 5 VDC (Optional 4 -20mA) |

| Response time | T90 in 7 Seconds |

| Sensor | Configurable |

| Sensor Type | Precision Electrochemical |

| Calibration | Periodically |

| Temperature Compensation | Integral |

| Flow Sensitivity | 0.5 – 5 SCFH |

| Pressure | 0.1 – 50 PSIG |

| Warranty | 12 Months Sensor 12 Months Electronics |

*Accuracy at constant conditions